Ultimate Guide to Aluminium Profile Cladding Tips for Effective Installation

When it comes to modern architecture, Aluminium Profile Cladding stands out. This material offers both aesthetic appeal and functional benefits. According to a recent report by Smith Research, the demand for aluminium cladding has grown by 22% over the past five years. This shift reflects its popularity in residential and commercial projects.

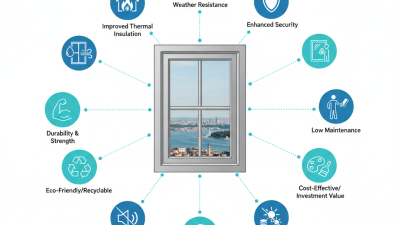

Aluminium Profile Cladding provides excellent weather resistance and insulation. However, the installation process can be complex. A survey from the Building Materials Association indicates that 30% of installations face issues due to improper techniques. This highlights the need for careful planning and execution during installation. Each project requires detailed attention to avoid common pitfalls like misalignment and inadequate sealing.

While Aluminium Profile Cladding is versatile, it's essential to consider the environmental impact. Although aluminium is recyclable, the energy used in production can be significant. It's crucial for builders and contractors to reflect on their choices. Striking a balance between aesthetics, functionality, and sustainability is vital for successful outcomes in cladding projects.

Understanding Aluminium Profile Cladding: Benefits and Applications

Aluminium profile cladding is becoming increasingly popular in construction. Its lightweight nature makes it easy to handle and install. This cladding material can significantly enhance the aesthetic appeal of buildings. It is widely used in both residential and commercial applications. The sleek design not only provides a modern look but also offers durability against various environmental factors.

When installing aluminium profile cladding, careful attention to detail is crucial. Ensure proper alignment during installation to avoid visible gaps. Use appropriate tools to cut the profiles accurately. This can prevent wastage and ensure a clean finish. Ventilation should not be overlooked as well. Proper airflow behind the cladding can prevent moisture accumulation.

Here are some helpful tips: always check for level surfaces before starting. This simple step can save you time later. Moreover, consider insulation options during the installation. This can improve energy efficiency in buildings. Remember that access to all areas is important. Make sure scaffolding is stable and compliant with safety regulations. Fine-tuning these details will lead to a better installation outcome.

Essential Tools and Materials for Aluminium Profile Cladding Installation

When embarking on an aluminum profile cladding installation, having the right tools and materials is crucial. Start with a sturdy measuring tape. Accurate measurements can prevent costly mistakes. A high-quality level ensures that everything aligns properly. Consider an aluminum cutting saw for precise cuts. The right saw saves you time and boosts the overall finish of your project.

In terms of materials, choosing the appropriate aluminum profiles is vital. Different thicknesses and finishes can affect durability and appearance. Don't forget a reliable adhesive or sealant. This will ensure a strong bond and increase weather resistance. Additionally, wearing safety goggles and gloves is essential. Protect yourself while working on sharp edges.

It's also wise to prepare for potential issues. Sometimes, the profiles may not fit as expected, leading to frustration. Always have a plan B for any unexpected challenges. It’s a learning experience; embrace mistakes as opportunities for improvement. Checking your work frequently helps catch errors early, avoiding bigger problems later on.

Step-by-Step Installation Process for Aluminium Profile Cladding

When it comes to installing aluminium profile cladding, a clear and systematic approach is crucial. Begin by measuring the area where the cladding will be applied. Accurate measurements are essential for minimizing waste and avoiding mistakes. Mark the wall with a pencil to outline the positions for the profiles. This helps visualize the layout. Use a level to ensure the lines are straight.

Next, prepare the surface. It should be clean, dry, and free of debris. Any imperfections in the wall might lead to alignment issues later. Be attentive to detail in this step. Gather your tools and materials beforehand to avoid interruptions. Cutting the aluminium profiles requires precision. Be cautious with sharp edges as they may cause injuries.

As you start the installation, secure the profiles with appropriate fasteners. Over-tightening can cause damage, while under-tightening may lead to loose fitting. Trust your instincts—the process can be tricky, and a second look can often help spot issues. After the profiles are up, check for consistency and alignment. If something seems off, re-evaluate your work. It's better to fix problems early than face larger issues later.

Ultimate Guide to Aluminium Profile Cladding Tips for Effective Installation

| Step | Description | Tools Required | Estimated Time |

|---|---|---|---|

| 1 | Prepare the Surface | Surface Cleaner, Brush | 1 hour |

| 2 | Measure and Cut Aluminium Profiles | Measuring Tape, Saw | 2 hours |

| 3 | Install Support Framework | Drill, Level | 1.5 hours |

| 4 | Attach Aluminium Profiles | Screwdriver, Screws | 2 hours |

| 5 | Finish and Clean Up | Cleaning Supplies | 30 minutes |

Common Challenges and Solutions in Aluminium Profile Cladding

When installing aluminium profile cladding, several challenges often arise. One common issue is misalignment during the installation process. Accurate measurements are crucial. A small error can lead to larger gaps. Ensure all profiles are level and aligned before securing them. Using spacers can help maintain correct positioning. It’s easy to overlook this step, but neglecting it can cause complications later.

Another challenge is dealing with weather conditions. Uneven exposure to the elements can affect adhesion and durability. For instance, condensation may form if cladding is installed in high humidity. It’s important to check the weather forecast and choose the right time for installation. Ignoring environmental factors can compromise the integrity of the cladding.

Finally, maintenance is often underestimated. Aluminium profiles may be resistant to rust, but grime and dirt accumulate over time. Regular cleaning is essential to maintain appearance. Some might forget this step as they focus on installation alone. A proactive approach can prevent long-term issues, ensuring the cladding remains effective and visually appealing.

Maintenance Tips for Longevity of Aluminium Profile Cladding

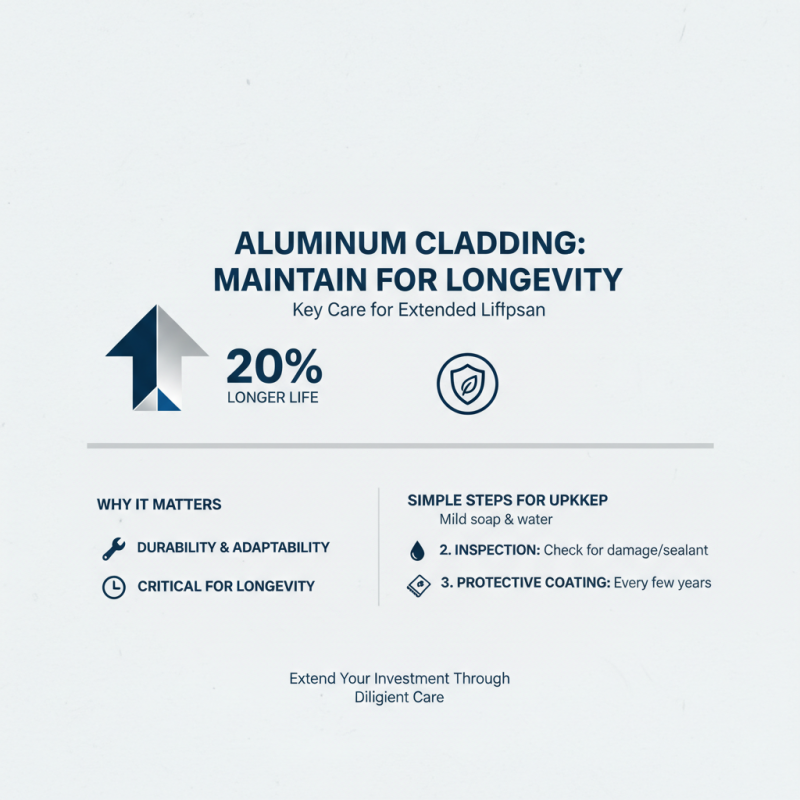

Aluminium profile cladding is gaining traction due to its durability and adaptability. However, maintenance is critical for ensuring longevity. Reports indicate that regular care can extend the lifespan of aluminium cladding by up to 20%. This remarkable resilience is achieved through diligent upkeep.

To maintain aluminium cladding, start with routine inspections. Check for any scratches, dents, or signs of corrosion. A mix of warm water and mild detergent is effective for cleaning. Use a soft cloth to prevent scratches. Don't underestimate the power of a good wash. It's essential for keeping your cladding looking new.

Another tip involves sealing gaps. If you notice any openings, seal them promptly. This simple action can prevent moisture infiltration, which is a leading cause of cladding damage. Additionally, consider periodic repainting every five to ten years. This not only enhances appearance but also provides an extra layer of protection.

However, maintenance can sometimes be overlooked. It's easy to assume that aluminium is invincible. The truth is, neglect can lead to costly repairs. Emphasizing preventative care is vital for sustaining your cladding’s integrity. Regular commitment can ultimately save both time and money.